9-Sept-2009

What is Finmet ?

What is Finmet ?

Finmet is a fluidized bed iron ore reduction process developed jointly by Fior de Venezuela and Voest Alpine (VAI) of Austria in 1991 based on the original Fior process operated in Venezuela. Two Finmet plants are currently in operation - one 2 Mtpa plant at Puerto Ordaz, Venezuela and another 2 Mtpa plant at Port Headland, Western Australia operated by BHP (now Bluescope).

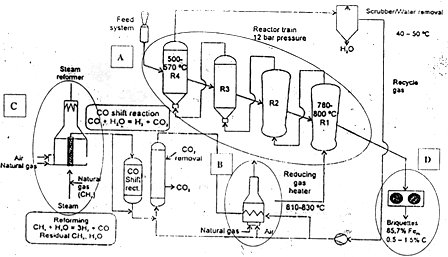

Fig: Flow-chart of Finmet Process

Finmet – The Process Concept

The Finmet process uses a train of four fluid bed reactors marked (A) in the adjacent figure with counter-current gas/solids contacting down the reactor train. The feed concentrate (iron ore fines of less than 12 mm size) is charged to the reactor train via a pressurized lock hopper system. The upper lock hopper in this system cycles continuously from ambient to reactor pressure to feed the ore continuously to the reactors maintained at the reactor pressure of 11-13 bars. The feed enters the topmost reactor (R4) where it is pre-heated to 550-570OC by the reducing gas leaving reactor (R3). Pre-heating, dehydration, decrepitation and reduction of hematite to magnetite take place in reactors R4, R3 and R2. The temperature in R1 is around 780-800OC and final reduction to 93% metallization is accomplished in this reactor accompanied by carburization of some of the Fe to iron carbide. The hot fine DRI (at 650OC) is then transported by a sealed system to the briquetting machine (D) to attain a briquette density of around 5 gm/cm3. The product from any Finmet plant is hence, HBI (Hot Briquetted Iron).

The gas required for reduction is a mixture of recycled top gas and fresh reformer make-up gas processed in a standard steam reformer from natural gas. The recycled gas (taken from the top gas leaving R4), is first quenched to 40-50OC and scrubbed in a wet scrubber to remove dust and water. The make-up gas required to balance the gas consumed by the reduction reactions is supplied from a conventional steam reformer system (C).

Finmet: Advantages and Disadvantages

Some of the advantages and disadvantages of Finmet process of iron making are :

=> It can use very large reserves of iron ore fines as feed stock unlike Midrex and HyL, which can use maximum 5% fines.

=> The output from a Finmet plant is HBI with Fe content varying from 91-94%, carbon 1-1.5% (or 3% maximum), metallization 91-93%.

=> Finmet’s operating pressure is as high as 12 bars to ensure higher degree of metallization. It has been reported that continuous operation at such high pressures has been a major problem in both the Finmet plants.

Related Articles –