5-Aug-2020

Refractories due to their chemical

complexity and phase change undergo fusion

(melt progressively) over a range of temperature. This softening behaviour or

refractoriness of any refractory material is determined by PCE test which is

done in a PCE furnace by comparing

ceramic specimen of known softening behaviour (either in ORTON or SEGAR Cones)

with the Cone of the refractory material. Value of PCE Cones in ORTON is

followed in British standard while SEGAR is in German standard of testing. To

view / download PCE Cone numbers with their temperature please click -

Refractories due to their chemical

complexity and phase change undergo fusion

(melt progressively) over a range of temperature. This softening behaviour or

refractoriness of any refractory material is determined by PCE test which is

done in a PCE furnace by comparing

ceramic specimen of known softening behaviour (either in ORTON or SEGAR Cones)

with the Cone of the refractory material. Value of PCE Cones in ORTON is

followed in British standard while SEGAR is in German standard of testing. To

view / download PCE Cone numbers with their temperature please click -

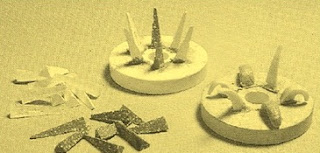

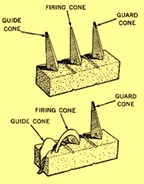

PCE Cones are small triangular ceramic

prisms of definite dimensions that when set at a slight angle bend over in an

arc so that the tip reaches the level of the base at a particular temperature

if heated at a certain rate (Refer Figures showing PCE Cones set on plaques

before and after firing). The bending of the Cones takes place after the

formation of a viscous liquid as a result of fusion of the Cone material. PCE

is measured by making a Cone of the refractory and firing it until it bends and

comparing it with standard Cone(s). Pyrometric

Cone Equivalent or PCE test is a must for the quality control purpose

for Refractories and Refractory raw materials.

PCE Cones are small triangular ceramic

prisms of definite dimensions that when set at a slight angle bend over in an

arc so that the tip reaches the level of the base at a particular temperature

if heated at a certain rate (Refer Figures showing PCE Cones set on plaques

before and after firing). The bending of the Cones takes place after the

formation of a viscous liquid as a result of fusion of the Cone material. PCE

is measured by making a Cone of the refractory and firing it until it bends and

comparing it with standard Cone(s). Pyrometric

Cone Equivalent or PCE test is a must for the quality control purpose

for Refractories and Refractory raw materials.

The thermal

softening behaviour of a refractory material technically known as ‘Refractoriness’, is determined by Pyrometric

Cone Equivalent (PCE) test. In other words, by Pyrometric Cone Equivalent (PCE)

of a refractory material we come to know about its ability to withstand exposure to elevated temperature

without undergoing appreciable deformation.

Refractories due to their chemical

complexity and phase change undergo fusion

(melt progressively) over a range of temperature. This softening behaviour or

refractoriness of any refractory material is determined by PCE test which is

done in a PCE furnace by comparing

ceramic specimen of known softening behaviour (either in ORTON or SEGAR Cones)

with the Cone of the refractory material. Value of PCE Cones in ORTON is

followed in British standard while SEGAR is in German standard of testing. To

view / download PCE Cone numbers with their temperature please click -

Refractories due to their chemical

complexity and phase change undergo fusion

(melt progressively) over a range of temperature. This softening behaviour or

refractoriness of any refractory material is determined by PCE test which is

done in a PCE furnace by comparing

ceramic specimen of known softening behaviour (either in ORTON or SEGAR Cones)

with the Cone of the refractory material. Value of PCE Cones in ORTON is

followed in British standard while SEGAR is in German standard of testing. To

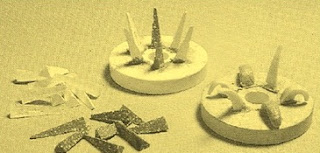

view / download PCE Cone numbers with their temperature please click - PCE Cones are small triangular ceramic

prisms of definite dimensions that when set at a slight angle bend over in an

arc so that the tip reaches the level of the base at a particular temperature

if heated at a certain rate (Refer Figures showing PCE Cones set on plaques

before and after firing). The bending of the Cones takes place after the

formation of a viscous liquid as a result of fusion of the Cone material. PCE

is measured by making a Cone of the refractory and firing it until it bends and

comparing it with standard Cone(s). Pyrometric

Cone Equivalent or PCE test is a must for the quality control purpose

for Refractories and Refractory raw materials.

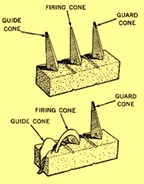

PCE Cones are small triangular ceramic

prisms of definite dimensions that when set at a slight angle bend over in an

arc so that the tip reaches the level of the base at a particular temperature

if heated at a certain rate (Refer Figures showing PCE Cones set on plaques

before and after firing). The bending of the Cones takes place after the

formation of a viscous liquid as a result of fusion of the Cone material. PCE

is measured by making a Cone of the refractory and firing it until it bends and

comparing it with standard Cone(s). Pyrometric

Cone Equivalent or PCE test is a must for the quality control purpose

for Refractories and Refractory raw materials.