23-Sept-2020

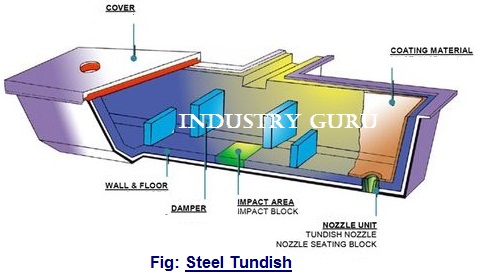

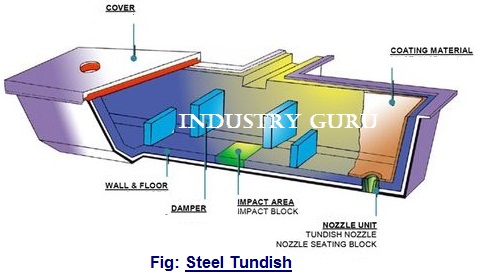

To transfer finished melt steel

from a ladle to mould in a continuous casting process, an intermediate vessel

is used which is called tundish. The role of tundish is to deliver the molten

metal to the moulds evenly and at a designed throughput rate and temperature

without causing contamination by inclusions. Inclusion float out, slag

vortexing, till end slab volume and residual metal in tundish are a strong

function of tundish hydrodynamics. Tundish design as well as flow control

devices / modifiers are known to have strong influence on tundish

hydrodynamics.

One of the major functions of

steel making tundish is to enhance inclusion floatability and thereby, produce

clean steel. For the removal of inclusion through floatation, wall adhesion and

agglomeration the flow patterns inside the tundish play an important role,

which in turn

Melt flow in any given tundish can be favourably altered by incorporating

suitable tundish flow modifiers (TFM) and/or changing the design of the

tundish. The flow modifiers play an important role in promoting the floatation

of nonmetallic inclusions in steel.

Now-a-days refractory makers

are offering customized refractory solution. The new age tundish refractories

facilitate temperature homogenization, removal of macro-inclusion, prevention

of nozzle clogging etc. inside tundish. To streamline the flow and compress

turbulence inside tundish various Flow Control Devices (FCD) are being used in

place of traditional FCDs or tundish furniture like Dams, Weirs, Charge Pads,

and Side Wall Pads etc.

The next generation FCDs are popularly known as Tundish

Flow Modifier (TFM), Tundish Flow Optimizer (TFO) etc. are precast

refractory shapes made of Ultra Low Cement Castables (ULCC) having 85 - 90%

alumina. The interior of tundish flow modifiers or flow optimizers as you say

it, are designed in such a way that incoming steel gets a churning effect which

results into inclusion flotation and subsequent absorption at the tundish

powder level. Tundish argon diffusers are also being used to reduce inclusion

in steel.

Eventually, it is tundish design from the viewpoint of metal flow and

appropriate selection of refractory materials with their right positioning

inside tundish that holds the key to the success of subsequent operations in

steel making.