What are Refractories? / What are Refractory Materials?

Refractories used are of both types -

Refractory items according to any standard dictionary are those materials which are hard to melt, fuse or work even under high pressure. Technically speaking Refractories are a large family of industrial lining and construction materials having melting point around 1200OC (+) and capable to withstand chemical & mechanical erosion, corrosion even under high temperature & pressure. For all high temperature operations, whether metallurgical viz. Steel, Aluminium, Copper, Zinc etc. or non-metallurgical viz. Glass, Fertilizer, Hydrocarbon, Chemicals, Paper, Cement etc. a refractory lining is necessarily required for their continuation with retention of heat in the furnace. For the above reasons refractories find their applications in lining construction of wall of all types of high temperature furnaces, kilns, reactors and other vessels wherever such operations are carried out. So directly or indirectly, virtually each of us is being constantly benefitted from refractories in our daily life.

Refractories used are of both types -

1. Those found as naturally occurring e.g. Basalt, Sillimanite, Carbon etc. and

2. Synthetic i.e. processed with natural or synthetic raw materials.

2. Synthetic i.e. processed with natural or synthetic raw materials.

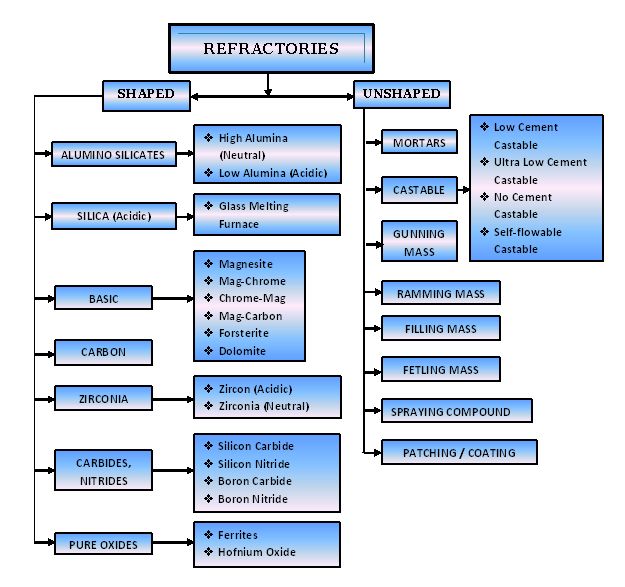

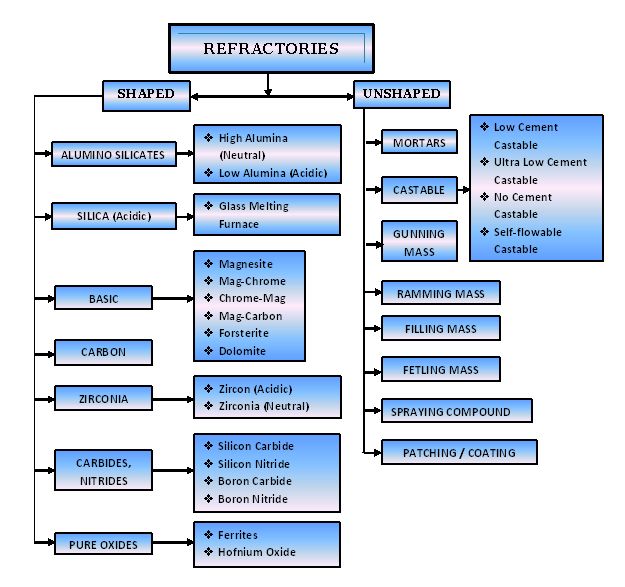

| SHAPED | UNSHAPED |

1. Alumino Silicates

3. Basic

5. Zirconia

| 1. Mortars 2. Castables

4. Ramming Mass 5. Filling Mass 6. Fetling Mass 7. Spraying Compound 8. Patching/Coating Mass |

Types of Refractories / Types of Refractory Materials

Refractories are classified into various categories (ref to the above Table). Refer to next article for details on Classification of Refractories.

Milestones and Developements achieved by Indian Refractory Industry:

India has an ancient history of ‘Potter’s Wheel’ which has, although remote, a definite link with the usage of refractory. Today India is producing and supplying almost all type of refractories (Shaped & Unshaped) equivalent to the International standard and quality. It took more than a century for India to attain this level by achieving milestones one after another. One such list of major developments (Milestones) which have taken place in the field of refractories in India is represented chronologically hereunder (ref to the Table below)

| Year |

Milestones Achieved

|

1874

|

|

1947

|

|

1949

|

|

1955

| |

1960

|

|

1969

|

|

1977

|

|

1983

|

|

1984

|

|

1985

|

|

1986

|

|

1988

|

|

1990

|

|

1991

|

|

1993

|

|

1994

|

|

1995

|

|

1998

|

|