Sillimanite belongs to the rich Alumino - Silicate group of minerals and is a polymorph of Kyanite and Andalusite represented by the chemical formula Al2SiO5. According to Wikipedia to this mineral has been named after American chemist Benjamin Silliman (1779 - 1864). Sillimanite is a very important refractory raw material especially, for high alumina refractories which are extensively used in Iron and Steel, Petrochemical, Electrical, Cement, Zinc and Glass industries.

Mineralogy of Sillimanite

Sillimanite is found as brown, grayish, pale green or white orthorhombic mineral with long slender, needle shaped crystals. Optically, it is subhedral, elongated, colourless and non-pleochroic (or colourless to pale brownish yellow) in plane polarized light. Sillimanite has low r.i., one set cleavage, and straight extinction in grains which are parallel to elongation. In pure form it has specific gravity 3.23 and Moh’s hardness 6 - 7.5.

Kyanite - Properties, Mineralogy and Indian Occurrences

Indian Occurrence of Sillimanite

Massive Sillimanite deposits of the Nongstoin state in the Khasi Hills of Assam (Meghalaya) in India commonly known as Assam Sillimanite, was the world famous for its quality and quantity. The host rocks were Cordierite - Biotite - Quartz - Muscovite - Gneiss or a Sillimanite - Quartz - Schist with intrusions of Granite. Now it is not available since the reserves have been depleted. The only other important occurrence is around Pipra in Madhya Pradesh (India) popularly known as Rewa Sillimanite and in Bhandara district of Maharashtra (India). The disadvantage of Rewa sillimanite is that it slightly sensitive to thermal shocks. An authorized supplier of Rewa / Bhandara sillimanite is M/s Pavri Kyanite Mines, Nagpur, Maharashtra. An alternate source is available today from Beach Sand (a by-product of Indian Rare Earths Limited, a Government of India Undertaking under its Department of Atomic Energy). One has to fulfill certain formalities with Indian Rare Earths Limited in order to procure sillimanite sand from them. The beach sand deposits are the potential sources of sillimanite along with rutile, ilmanite, monazite, garnet, zircon and quartz. The Chavara (Kerala, India), Manavalakurichi (Tamil Nadu, India) and Chatrapur (Orissa, India) are among the richest deposits in the world. Indian beach sand deposits contain about 9% rutile, 6% garnet, 3% sillimanite and 1% monazite and zircon. After magnetic removal of Monazite, sillimanite, garnet, zircon and rutile are separated from one another by gravity tabling, electrostatic and flotation techniques.

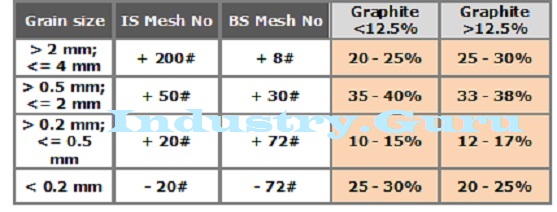

The following table shows the Chemical Composition of Sillimanite of two different sources:

| Constituents (%) | Rewa / Bhandara | Indian Rare Earths (Beach Sand) |

| LOI Al2O3 SiO2 Fe2O3 CaO MgO Na2O K2O TiO2 / ZrO2 | 5.00 57.50 33.30 0.70 -- 0.15 -- -- 2.16 (TiO2) | 0.40 60.37 36.30 0.27 1.36 Trace 0.06 -- 0.60 (ZrO2)

|