6-July-2020

|

| Mag Carbon Bricks |

Magnesia

carbon refractory bricks (MgO-C) or Carbon containing Magnesite refractories

have been extensively used by steel makers for the secondary treatment of steel

in basic oxygen furnaces, electric arc furnaces, and ladle furnaces. Mag Carbon

refractory bricks are widely used in slag lines of BOF (Basic Oxygen Furnace) because

of their superior wear resistance. The service life of Magnesia Carbon

refractories used in BOFs have been pushed quite significantly (largely due to

slag splashing and gunning improvements) even as the service conditions have

become more severe due to the increased operating temperature required for

continuous casting and the need to produce cleaner steel.

Mag Carbon

bricks are made of high purity magnesia, high quality graphite, antioxidants

and some additives with a suitable binder (bonding agent). Selection of raw

materials, their grading and grain size distribution (Granulometry) and

composition together have ultimate role in the development of various physical

properties, microstructure and ultimately thermo-mechanical properties of Mag Carbon

refractory bricks (MgO-C). Various different types of MgO (Magnesite) grains

provide different levels of corrosion resistance.

From

the literature and plant applications it has been established that

Magnesia-carbon bricks having 3 mm particle size show better wear resistance as

well as a few other characteristics as compared to the bricks with 5 mm size

grains.

Graphite, Anti-Oxidants

(Additives) and Binders used in the composition of Magnesia Carbon Bricks

The

graphite flakes used in these bricks impart -

=>

High thermal conductivity

=>

Good thermal shock resistance

=>

Low thermal expansion

=>

Non-wettability by liquid slag

=>

Low corrosion rates by slags

Graphite

contents of typical bricks range from 4 - 35% natural flake graphite. Since

oxygen affinity of carbon is very high so different kinds of antioxidant

minerals are used (in fines or superfines) in order to protect refractory

material against chemical corrosion. The REDOX reactions in magnesia carbon can

be reduced by selection of high purity magnesite, large crystal size and use of

graphite with low impurities. Slag corrosion resistance of MgO-C refractories

can be improved by use of magnesite grains with less reactivity i.e. fused

magnesite grains of high Bulk Density (BD) and high purity.

The

above are some of the reasons which explain how selection of various raw

materials can affect the performance of magnesia-carbon bricks. More on this

aspect and the compositions of Magnesia-carbon refractory bricks will be

discussed in a separate post:

Here,

our topic is Granulometry i.e. overall grading and the grain size distribution,

suitable for the best performance of MgO-C bricks. Grading and the grain size

distribution are important as these are directly related with the following

properties of Magnesia-carbon bricks:

=> Porosity

=>

Mechanical strength

=>

Spalling resistance

=>

Microstructure and phase development

=>

Wear resistance

From the

experience of various trials and performances it has been found that 0 - 4 mm

grading is the best for MgO-C refractory bricks for all general applications and

also for different shapes like Tap Hole Blocks, Sleeves, etc. (except Slide

Gate refractories which will be different).

Bonding

agents or binders used in Mag Carbon bricks and other carbon refractory

products are immiscible with graphite and other refractory raw materials. At

room temperature, they rely on binder to cure. Generally these binders or

bonding agents are resin, asphalt or an organic matter and can be divided into

three types: phenolic resin, modified asphalt, petroleum cracking by-product

category.

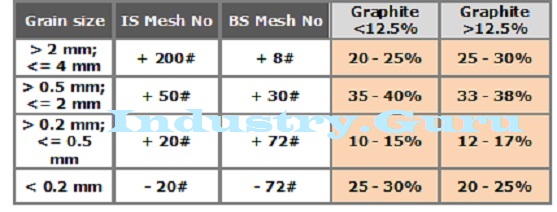

The grain

size distribution (granulometry) of the press mixture (powder) for MgO-C bricks

with different Graphite percentages as they should be are given in the

following table: