24-April-2010

With the advancement of technology and involvement of very high temperatures by various industries as well as continuously increasing energy costs, there has been always a demand for new and more dependable insulating materials. Finally, there has been one of the most exciting developments in the field of high temperature insulation as ceramic fibers. These are a family of insulating refractory products based on refractory or ceramic fibers. Such products are very light and highly porous resulting in an excellent insulating efficiency with decrease in the material consumption of insulators by 40 to 60 percent. Thus use of such materials reduces overall weight of the structure, reduces fuel consumption and increases the productivity. These materials have seen rapid sales growth in recent years because of their excellent insulating properties, light weight, and ease of installation. Most refractory fiber materials are basically high temperature fiberglass materials. They have alumina-silica compositions made from pure alumina and silica or from kaolin clay. There are also chemically made alumina (Al2O3) fibers which are useful for high temperatures but which are quite expensive. Zirconia fibers (generally glass bonded zircon) have also found considerable market acceptance for service up to 3300OF or even a little higher. [Insulating refractories in general, their types, raw materials used for their manufacturing, method of heat - flow through such refractories and its calculations, what should be the thickness of insulating refractory linings etc. have been discussed in detail in posts Insulating Refractories (Part - I) and Insulating Refractories (Part - II)].

With the advancement of technology and involvement of very high temperatures by various industries as well as continuously increasing energy costs, there has been always a demand for new and more dependable insulating materials. Finally, there has been one of the most exciting developments in the field of high temperature insulation as ceramic fibers. These are a family of insulating refractory products based on refractory or ceramic fibers. Such products are very light and highly porous resulting in an excellent insulating efficiency with decrease in the material consumption of insulators by 40 to 60 percent. Thus use of such materials reduces overall weight of the structure, reduces fuel consumption and increases the productivity. These materials have seen rapid sales growth in recent years because of their excellent insulating properties, light weight, and ease of installation. Most refractory fiber materials are basically high temperature fiberglass materials. They have alumina-silica compositions made from pure alumina and silica or from kaolin clay. There are also chemically made alumina (Al2O3) fibers which are useful for high temperatures but which are quite expensive. Zirconia fibers (generally glass bonded zircon) have also found considerable market acceptance for service up to 3300OF or even a little higher. [Insulating refractories in general, their types, raw materials used for their manufacturing, method of heat - flow through such refractories and its calculations, what should be the thickness of insulating refractory linings etc. have been discussed in detail in posts Insulating Refractories (Part - I) and Insulating Refractories (Part - II)].

Refractory fiber products can take on a variety of forms.

Bulk fiber can be used for packing or stuffing. The fiber can be collected into a mat and wetted with an organic binder. When this binder is cured it yields a felt. Available in flexible rolls in densities of 3, 4, 6, and 8 pcf (lb/ft3) or in sheets passed to densities as high as 24 pcf, these felts have served a wide variety of purposes. Another development has been the production of binder-free blankets. Often these have the fibers mechanically interlocked by a “needling” process which substantially increases mechanical strength without the using any organic binder. Mechanical strength at high operating temperatures is thus preserved, since any organic binder burns out during initial heat-up. Refractory fibers can also be vacuum formed to give rigid board and shapes, such as combustion chambers. A tremendous variety of products have thus resulted. Just to mention a high technology application, the insulating tiles on the re-entry surfaces of the Space Shuttle are of this type. Formulated of ceramic fibers and with a special ceramic bond, those tiles are capable of withstanding extremely high surface temperatures and temperature gradients without failure, while protecting the vehicle substructures by virtue of their very low thermal conductivity.

Refractory Fiber products have unique properties.

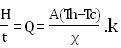

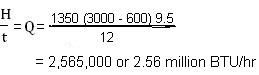

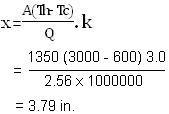

In many respects they have revolutionized insulating refractory lining technology. Refractory Fiber products have exceptionally low thermal conductivity values, as can be seen in the adjacent figure (graph) given for typical refractory fiber blanket products. Note that the higher density materials have lower k values. Most of the heat transfer occurring in fiber products is by radiation. Higher density fiber products have more fibers in the same volume and thus block radiation more effectively. Solid conduction is minimal, since an 8 pcf fiber blanket contains 95% air. Air conduction is also important, however. Note that the k values increase rapidly as the temperature increases. This too, is the result of the major role that radiation plays in energy transport in refractory fiber materials. The low density of refractory fiber means that very lightweight insulation systems are possible. Furnace or kiln linings can be exceptionally light. This also results in very low heat storage, which is very important in cyclical operation. It allows rapid heat-up and cool-down and is a major factor in energy conservation with these materials. Insulating refractory fiber linings also greatly reduces the mechanical load on supporting structures, so that these can be made lighter and less expensive. The resilience of fiber materials makes thermal shock practically impossible. Extraordinarily rapid temperature changes have no effect on refractory fibers or their mats. Various types of felts based on ceramic fibers and available in rolls have proved to be useful as their use promote speedy laying with minimum joints. They also guarantee a unique advantage of lining surfaces bearing complicated contours.

TABLE: Thermal Comparison of Refractory Fiber Lining with IFB and Fireclay

Brick Linings for Furnace Operating at 1800OF

Wall Construction

|

Heat Loss (BTU/ft2/hr)

|

Heat Storage (BTU/ft2)

|

Cold Face (OF)

|

Lining Weight (lbs/ft2)

|

9 in. fireclay brick

9 in. 2000OF IFB

6 in. refractory fiber (3 in. 8 pcf blanket, 3 in. mineral wool back-up)

|

1239

201

220

|

23400

4603

1546

|

424

175

182

|

98

22

5.75

|

Like all refractories, fiber materials do have some limitations.

The chief limitation is shrinkage at high temperatures. A high quality ceramic fiber blanket rated for continuous use at 2400OF will have 5% shrinkage after 24 hr exposure at 2400OF. Shrinkage will not continue past this level in normal operating conditions, but this shrinkage must be carefully considered in designing a furnace lining. The mechanical strength of ceramic fibers is understandably poor. Even the rigid vacuum formed products are not really structural materials. Proper support must be given to all refractory fiber products. Since these are for most part glass fiber materials, they may sag at high temperature due to softening of fibers if improperly supported. Devitrification also occurs, causing a loss of resilience. Since their first introduction to the market, refractory (ceramic) fiber products have been considerably improved in many of these respects. Their manufacturers are happy to call attention to those improvements; but in every case it is wise to pay close attention to the properties of fiber materials and to the technical design and installation advice given by their prior users. A limitation that is always present is that fiber insulating materials are handy repositories of dusts, fogs, and combustible fumes; not to mention for process liquids like slags and metals. These materials are definitely not indicated for service in such severe environments. They are used with great success, on the other hand, in metal treating furnaces, ceramic kilns, and numerous other periodic operations whose atmosphere do not negate their revolutionary thermal and lightweight qualities. Fiber mats also continue to be used in expansion joints and door seals, and in tunnel kilns and other exposed - brick structures as either original or retrofit layers on the outside or cold-face surface.

Refractory fiber materials tend to be more expensive than conventional refractories, although that differential has shrunk or disappeared as fiber prices have held more or less steady. Installation labour savings and energy savings have made refractory fiber the most economical material in a very wide variety of ‘clean’ applications. It is the combination of low heat loss and low heat storage that make fiber so attractive.

Our next post is on the subject: