11-Sept-2009

Fastmet – The Process Concept and References

Fastmet – The Process Concept and References

This is a direct reduction process using a Rotary Hearth Furnace (RHF) which was derived from the work done in USA by Midland Ross and Surface Combustion, in the ‘Heat Fast’ process, treated in 1960s. It is a solid reductant based process in which iron ore concentrate, pulverized coal and a binder are mixed together and pelletized. The resulting green pellets are fed either to a drier or directly to a rotary hearth furnace where the pellets are heated to 1250 - 1400OC and reduced to metallic iron. Burners and post-combustion the CO evolved provide the heat required to raise the pellets to the reduction temperature.

The first commercial Fastmet plant was commissioned at the Hirohata Works No.1 of Nippon Steel in April, 2000 and Hirohata Works No.2 in February, 2005 with material processing capacities of 190000 tpa each plant. The second plant established was Kobe’s Steel’s Kakogawa Works started from April, 2001 having a material processing capacity of 16000 tpa. The Fastmet process has allowed the Kakogawa Works to achieve a zero emission rating of steel mill waste. Waste utilization is the principal application of the Fastmet process in Japan.

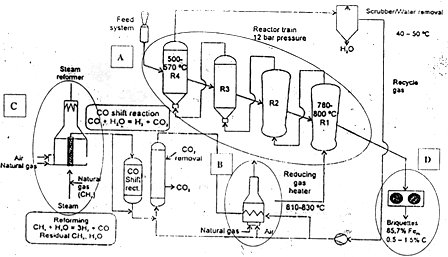

FASTMET Process - Flowchart

Advantages of Fastmet

Some of the advantages of Fastmet process as have been reported are summarized as follows:

=> A wide variety of iron ore as well as steel mill wastes including BF dust, BF Sludge, BOF dust, Sinter dust, EAF dust, mill scale, and etc. can be used as the oxide feed.

=> Elimination of waste disposal cost and landfill liability as wastes is changed to a quality source of iron (DRI).

=> Recovery of Zinc contained in wastes (Zn deriving from scrap) which can be sold to zinc producer. Zinc removal: 95% or higher.

=> A wide variety of energy sources can be utilized including natural gas, LPG, coke oven gas, heavy oil, coke breeze and carbon bearing wastes or pulverized non-coking coal.

=> The short reduction time of less than 12 minutes enables easy plant starting and shut-down, and quick adjustment of production rate.

=> Reclamation of carbon is possible. Carbon contained in dusts will be used as reductant. The carbon content of DRI can be adjusted as per the customer’s requirement.

Related Articles –